What is the strength of ceramic fiber board?

- 20 Aug, 2025

- Industry

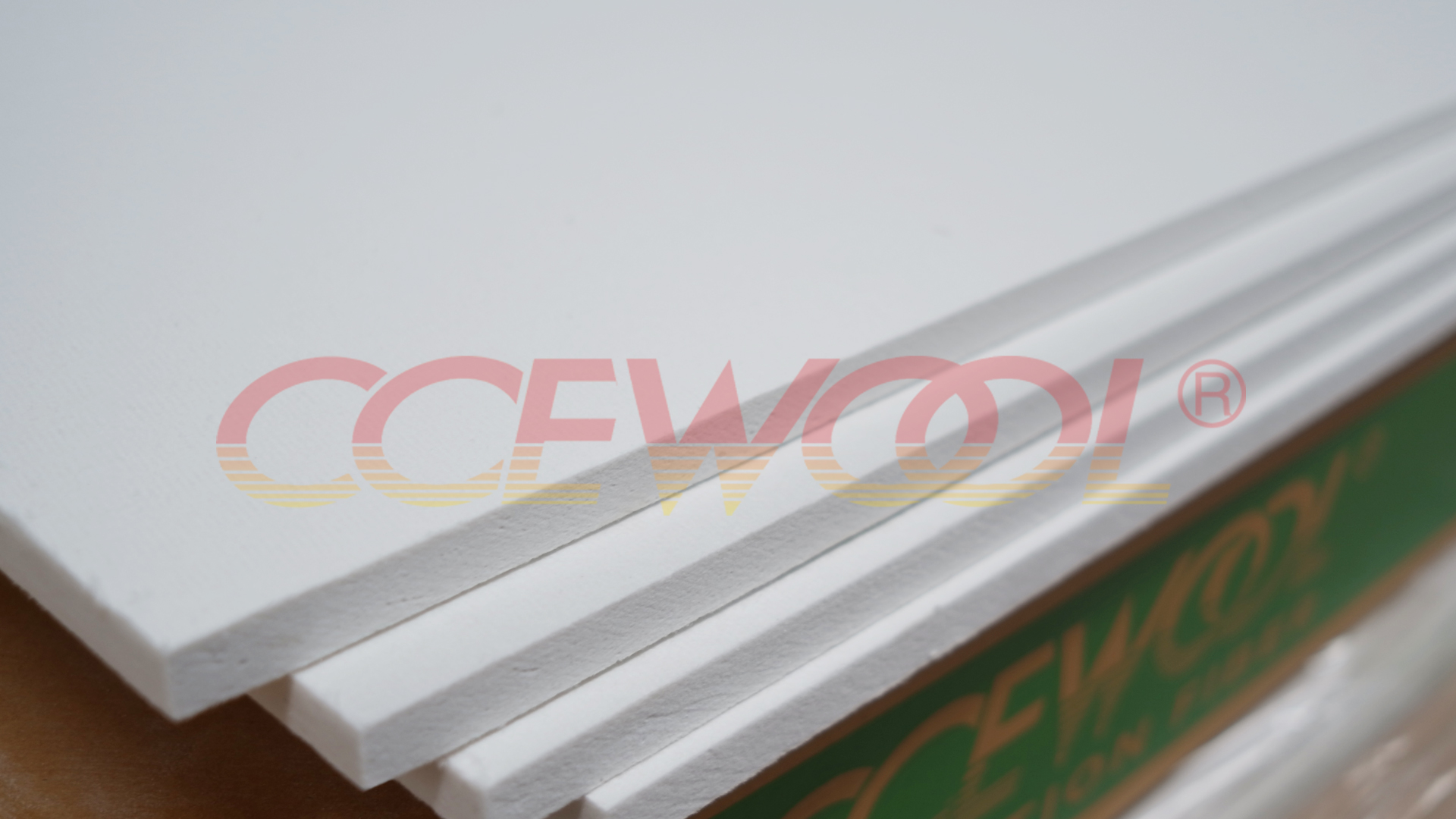

Ceramic fiber board is a lightweight, high-temperature insulation material widely used in industries such as metallurgy, glass, ceramics, heat treatment, and power generation for furnace walls, roofs, and back-up insulation layers. While its temperature resistance and thermal insulation performance are often emphasized, the strength of a ceramic fiber board is equally critical.

High strength ensures the board can maintain its shape and structural stability under heat and mechanical stress, resisting powdering or collapse, and guaranteeing safe, long-term operation of high-temperature systems.

Why is high strength important?

Withstands mechanical stress during installation and operation

During transport, cutting, and installation, ceramic fiber boards are often subjected to impact, compression, and bending. High-strength boards avoid breakage and chipping. In service, mechanical stress from hot gas flow, vibration, and frequent door openings is common, and strong boards maintain their stability.

Handles thermal shock and temperature fluctuation

Frequent start-stop cycles or temperature swings generate significant thermal stress. Low-strength boards may crack or delaminate, while high-strength boards can adapt to these conditions without damage.

Extends service life and reduces costs

Stronger boards resist powdering and collapse, preserving insulation performance over time, reducing replacement frequency, and lowering maintenance expenses.

Adapts to complex installation environments

In areas like furnace roofs, walls, irregular shapes, or large spans, high strength ensures the board will not sag or break due to its own weight or thermal deformation.

How does CCEWOOL® produce high-strength ceramic fiber board?

- High-purity raw materials

CCEWOOL® uses in-house melted, high-purity spun ceramic fiber bulk. The long fibers and low shot content create a stronger, more uniform bonding structure. - High-precision vacuum forming

Our precision vacuum forming process ensures uniform fiber distribution in three dimensions, creating a dense and balanced structure that enhances overall board strength. - Optimized inorganic binder system

Using high-temperature, corrosion-resistant inorganic binders ensures that the board maintains bonding strength at elevated temperatures, without loosening or delaminating due to binder decomposition. - Intelligent temperature-controlled high-temperature sintering

After forming, the boards are sintered under carefully controlled conditions to fully integrate the fibers and binder, significantly improving mechanical strength and thermal shock resistance. - Dimensional and density consistency

Automated cutting guarantees precise dimensions, while consistent density ensures better installation fit and structural stability at high temperatures.

In high-temperature industrial applications, strength is not just a physical property of ceramic fiber board—it is a core factor that determines its value and cost-effectiveness.

Through high-purity raw materials, precision forming, optimized binder systems, and high-temperature sintering, CCEWOOL® delivers ceramic fiber boards with exceptional strength and stability, providing reliable, long-lasting insulation solutions for industries worldwide.