Customer Feedback | CCEWOOL® Full Range Insulation Materials Gain Strong Recognition Again

- 19 Nov, 2025

- Company

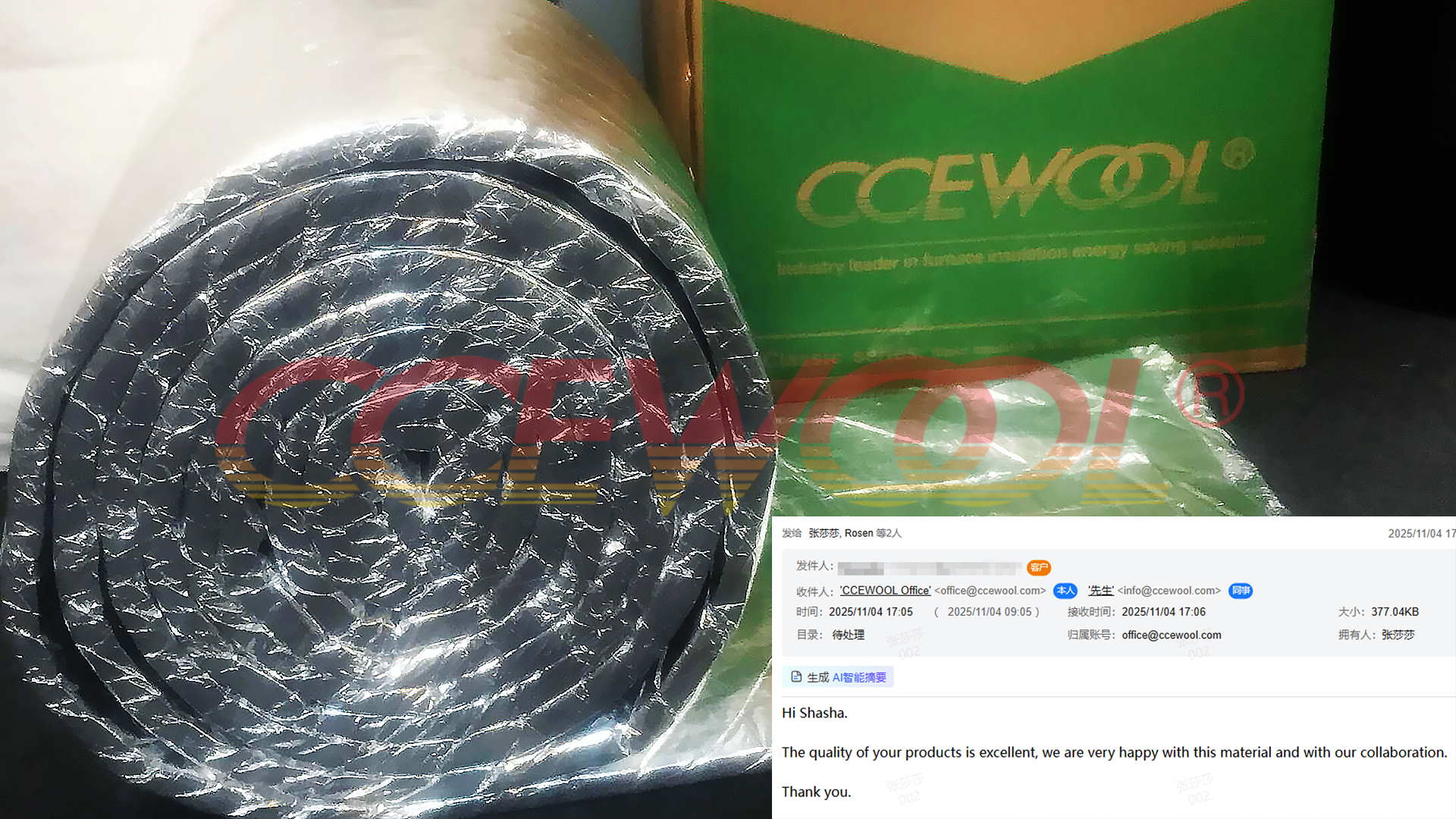

Recently, CCEWOOL® received direct feedback from our customer:

“The quality of your products is excellent, we are very happy with this material and with our collaboration.”

A short sentence — but this evaluation came after actual operation and real furnace conditions, proving that CCEWOOL® products withstand real industrial testing, not just lab specifications.

This customer ordered one full 40HC container of mixed insulation materials, including:

CCEWOOL® 1260 Ceramic Fiber Wrap

CCEWOOL® 1200 Low Biopersistent Fiber Wrap

CCEWOOL® 1260S Ceramic Fiber Blanket

CCEFIRE® Insulating Fire Bricks

This mixed configuration covers multiple temperature ranges and different furnace structural zones — from hot-face insulation, to environmental-friendly AES fiber zones, to structural back-up layers using IFB.

This purchasing pattern reflects strong trust in CCEWOOL®'s capability to supply complete insulation solutions, rather than single product categories.

CCEWOOL® insists on high-purity raw material systems, advanced fiber homogenization control, and intelligent manufacturing parameter management — ensuring stable thermal conductivity, high anti-powdering performance, uniform fiber structure, and long service durability.

This helps customers reduce heat loss, extend lining lifetime, reduce unexpected maintenance shutdowns — and ultimately lower total running cost of the entire thermal system.

We believe quality is never the result of one process — but the outcome of a full production logic, technological discipline, and strict quality control system.

Customer feedback is the strongest proof of CCEWOOL® product strength and service value.

CCEWOOL® will continue to supply global customers with a professional insulation product matrix and stable global warehouse support — helping more industrial users improve furnace efficiency, achieve long-term energy-saving performance, and secure stable operations.